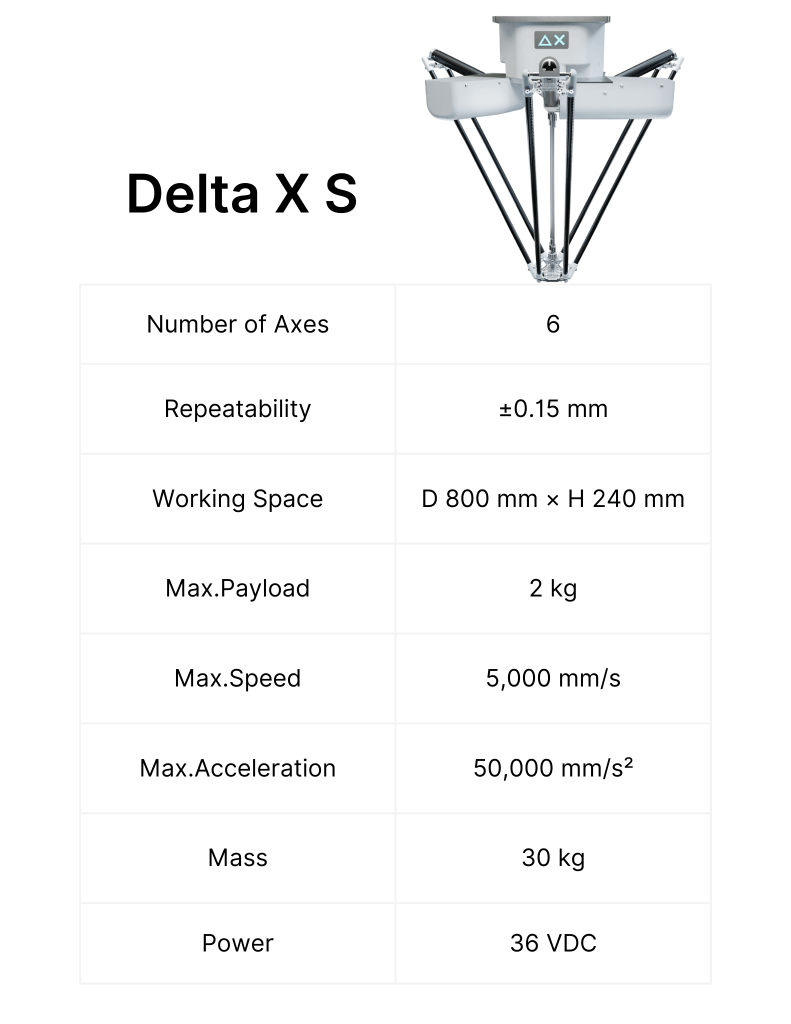

Ideal for light industry:

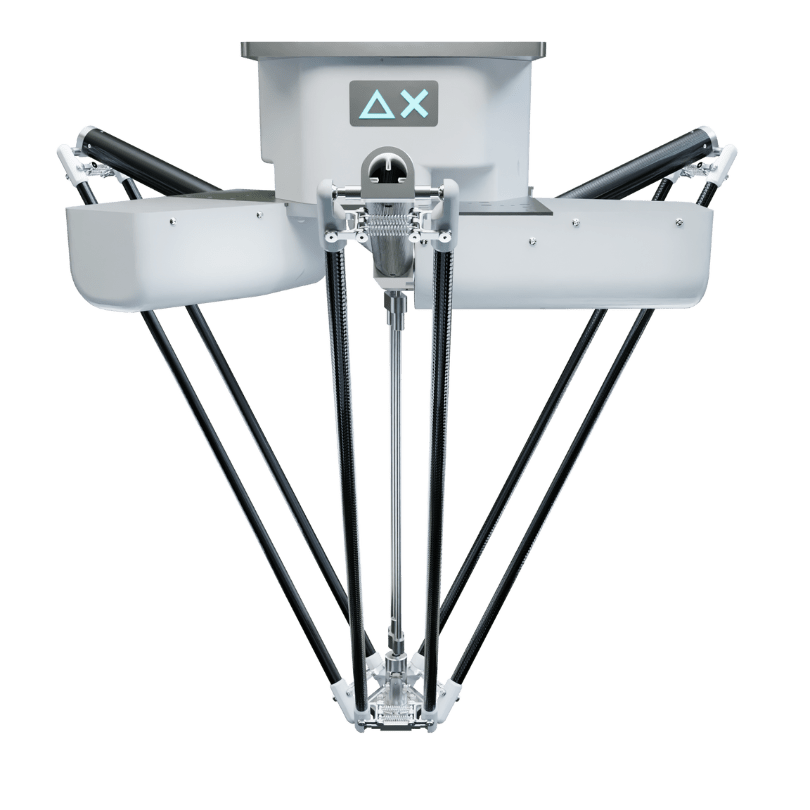

It can tilt, twist, and rotate the end-effector, enabling complex tasks that simpler delta robots cannot achieve.

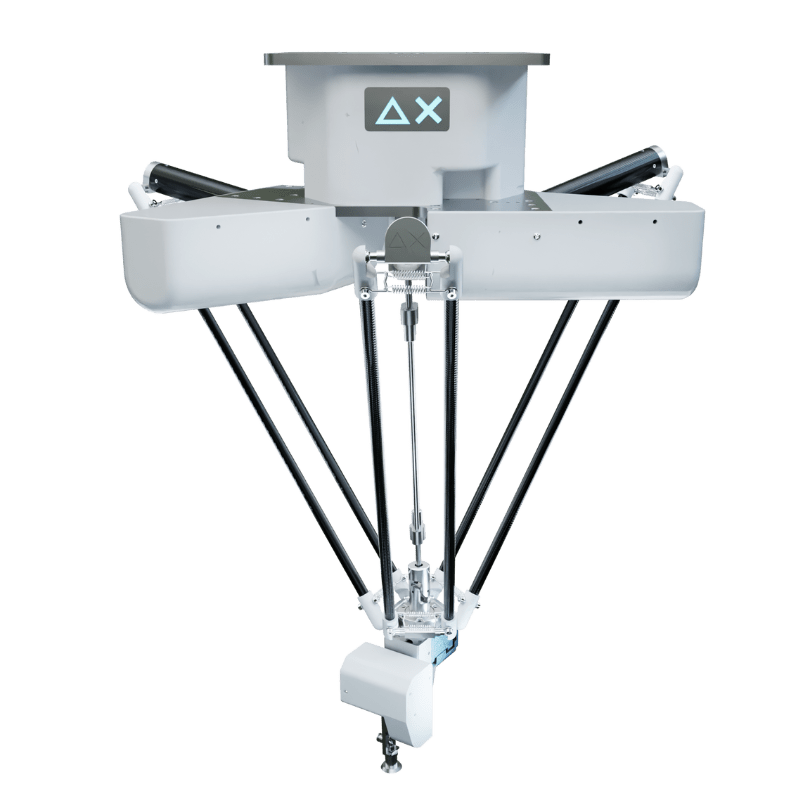

Choose between Ø 400 mm, Ø 600 mm, or Ø 800 mm

Ø 400 mm

Ø 600 mm

Ø 800 mm

DeltaX Studio combines built-in vision and Blockly to unify perception and motion for fast, reliable, real-time delta robot workflows.

* DeltaX Studio is pre-installed when you purchase the Edge AI Computer.

We provide a complete service suite to help you get the most from your Delta X S robot.

Design and build end-effectors tailored to your specific parts and processes.

Get ready-to-run pick-and-place demos or custom vision examples for rapid deployment.

Access real-time remote assistance and updates directly from the DeltaX team.

Contact us to ask anything from delta robot to smart sorting solution.

Affordable & Efficient Delta Robot

Software

Support

© All Rights Reserved by DeltaX Robotics 2024