Introduction

Delta robots are the unsung heroes behind many ultra-fast pick-and-place operations in modern factories. Ever wondered how a packaging line can sort candies or components in the blink of an eye? Chances are, a delta robot is doing the heavy lifting – or rather, the light-speed moving. In this beginner-friendly guide, we’ll explore what delta robots are, how they work, their advantages, and how they’re transforming industries. By the end, you’ll understand why these spider-like machines are a big deal in automation, and we’ll introduce the DeltaX Delta Robot Series as a real-world example of their evolving capabilities.

1. What Is a Delta Robot?

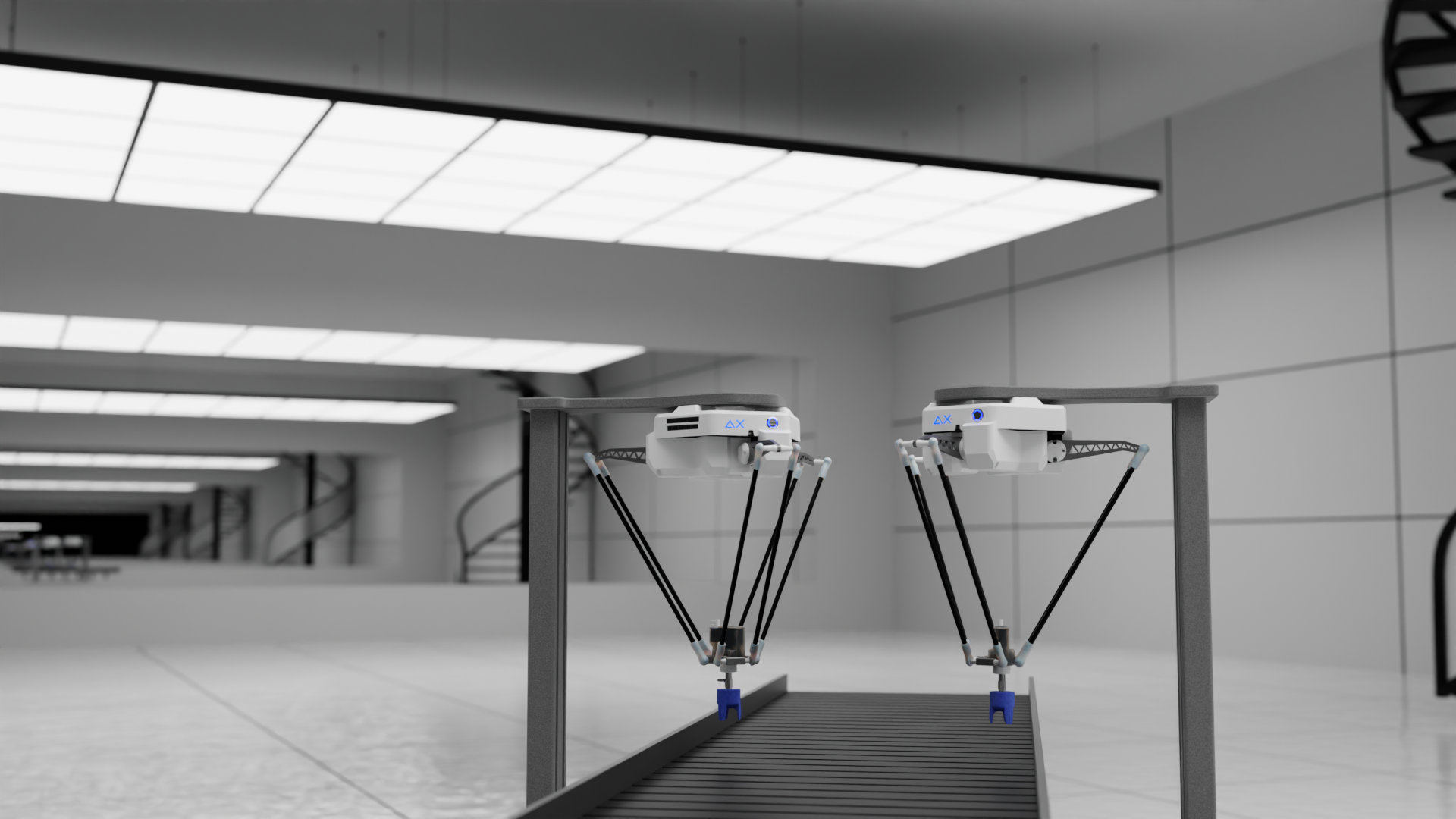

A delta robot is a type of parallel industrial robot known for its lightning-fast movement and precision. Unlike the typical robotic arm you might imagine, a delta robot consists of three slender arms connected to a common base, working in unison to manipulate a single end-effector (like a gripper or suction cup). Its signature triangular arrangement keeps the moving parts lightweight and agile.

- Parallel Linkages: Each arm usually contains parallelogram linkages, so the end effector (tool) stays level at all times.

- Lightweight Moving Parts: Motors remain at the top (on the fixed base), meaning only light rods move, enabling very high speed.

- Dome-Shaped Workspace: Delta robots typically operate in a cone or dome beneath their base, making them perfect for fast pick-and-place tasks directly below their mounting point.

Delta robots are sometimes called “spider robots” due to their appearance. Because their motors are all fixed on the base, and only the arms move, they can accelerate and decelerate extremely quickly. In fact, some models reach speeds of up to 300 picks per minute – perfect for high-volume operations such as sorting and packaging.

2. How Do Delta Robots Work?

Despite their complex looks, delta robots operate on a straightforward principle: multiple arms moving together to control one platform. Here’s a quick breakdown:

- Triangular Base with Three Arms: A delta robot’s base is mounted above the work area. Attached to this base are three motor-driven arms arranged in a triangular formation. Each motor raises or lowers its arm.

- Parallelogram Linkages: Each arm includes a parallelogram linkage that ensures the end effector does not rotate when the arms move – it only shifts in X, Y, Z directions.

- Universal Joints: The arms connect to the base and to the end effector with ball-and-socket joints, allowing pivoting motion without losing rigidity.

- Lightweight Mechanics: Heavy motors stay fixed on top; only thin rods move. This low mass allows for rapid acceleration and precision, which is why delta robots excel at pick-and-place tasks.

- Dome-Shaped Workspace: As the motors drive the arms, the end effector moves throughout a dome or cylindrical volume below the base. This shape lets it swoop in, grab items, and reposition them in milliseconds.

3. A Brief History of Delta Robots

Delta robots were invented in the early 1980s by Professor Reymond Clavel and his team at EPFL, Switzerland. They initially wanted a faster way to pick up praline chocolates and place them into packages. By placing motors at the base and using light rods, the first delta robot achieved the high speed and accuracy needed for packaging chocolates without damage. In the 1990s, several major robotics companies (like ABB) commercialized the idea, naming their delta robots “FlexPicker,” and it soon became a staple for food packaging lines and other manufacturing tasks worldwide.

4. Advantages of Delta Robots

Delta robots stand out for several reasons:

- Blazing Speed: Their low moving mass makes them some of the fastest industrial robots, often exceeding 100–200 picks per minute.

- High Precision: Parallel linkages keep the end effector stable and repeatable, allowing ±0.1 mm accuracy in well-tuned setups.

- Small Footprint: They’re typically mounted overhead, saving valuable floor space.

- High Throughput: One delta robot can replace multiple human operators in repetitive tasks, and several delta robots can work in unison for massive output.

- Low Wear & Maintenance: Motors stay at the base, reducing mechanical stress on the arms, which leads to simpler maintenance.

These advantages make delta robots ideal for light, repetitive tasks: picking, packaging, sorting, small assembly, and more. While they’re typically limited to dome-shaped work envelopes and lighter payloads, the speed gains they offer are unmatched.

5. Common Applications of Delta Robots

- Food & Beverage Packaging

- Sorting candies, cookies, or chocolates at high speed

- Placing baked goods into packaging without damaging them

- Maintaining strict hygiene standards

- Pharmaceutical & Cosmetics

- Rapid handling of pills, vials, or small packaging tasks

- Vision-guided sorting to ensure correct labeling and orientation

- Electronics Assembly

- Placing small components onto circuit boards

- Inspecting parts or arranging them with sub-millimeter precision

- Pick and Place Sorting

- Removing defective items from a conveyor

- Organizing mixed items into separate bins based on type or size

- Quality Inspection

- Checking product orientation, defects, or completeness

- High-speed “scan and reject” systems

- 3D Printing / Maker Projects

- Some Delta robots are adapted into 3D printers (Delta configuration)

- Education and R&D environments testing new applications

6. The DeltaX Delta Robot Series

To see how delta robots are evolving for broader use, check out the DeltaX Delta Robot Series. These robots embody the core strengths of delta robots—speed, precision, efficiency—across several models:

Delta X 1

- Open-Source Educational Delta Robot

- Great for R&D, classroom projects, and hobbyists

- Compact and modular; can even swap in a 3D printing head or laser engraver

- Low cost of entry so students and startups can explore delta robotics without breaking the bank

Delta X 2

- Enhanced Desktop for Light Manufacturing

- Faster and stronger than X1; handles up to ~700 g payload

- Ideal for small production lines, labs, and pilot automation setups

- Maintains a desktop-sized footprint while delivering near-industrial performance

Delta X 3

- Industrial-Grade Performance in a Compact Form

- Achieves up to 2200 mm/s speed, ±0.15 mm precision, ~1 kg payload

- Perfect for mid-level manufacturing tasks where you need serious throughput but limited space

- Balances power and size to fit on a standard workbench or production cell

Delta X S

- High-Speed 6-Axis Delta Robot for Heavy-Duty Tasks

- Reaches speeds up to 5000 mm/s with ±0.15 mm repeatability

- Can lift up to 2 kg without losing speed or precision

- Offers up to 6 degrees of freedom (3 main delta axes + rotational axes) for complex pick-and-place and orientation tasks

- Built for large-scale automation, from high-throughput packaging to advanced inspection lines

Each model targets a different scale of usage—from a classroom or startup’s first taste of automation (X1) to a full-on industrial workhorse (X S). This progression demonstrates how delta robots are becoming accessible and affordable even for smaller enterprises.

7. Why Delta Robots Matter for the Future

Delta robots may have started in the confectionery world, but their high-speed talent and efficiency have made them indispensable in modern manufacturing. As more industries strive for faster output, better quality, and lower costs, delta robots fit the bill. They seamlessly slot into production lines, work tirelessly around the clock, and help companies maintain a competitive edge.

Here’s why they’ll keep playing a big role:

- Growing Demand for Automation: Labor shortages and the push to reduce repetitive human tasks are fueling rapid robot adoption.

- Innovation in Design & Accessibility: Models like Delta X S are more affordable and user-friendly than ever, opening the door for SMEs and startups.

- AI & Vision Integration: Pairing delta robots with camera systems and machine learning allows for smart picking, defect detection, and flexible adaptation to new products or SKUs.

- Scalability: Because delta robots mount overhead, manufacturers can add multiple units side-by-side for massive parallel throughput.

Closing Thoughts

When you need lightning-fast pick-and-place for small objects, delta robots are hard to beat. They blend ingenious design (motors on top, lightweight arms) with raw speed and precision, becoming the go-to choice in packaging, assembly, and a host of other applications. Whether you’re seeking a student-friendly robotics kit or a high-throughput industrial solution, the DeltaX Delta Robot Series shows just how far this technology has come—bringing delta robots from specialized factories to broader markets and even classroom desks.

Curious about implementing a delta robot? Explore DeltaX Robotics or look into other delta solutions to see how these spider-like machines can transform your production line. Whether it’s sorting candies or assembling circuit boards, delta robots help you automate at speeds humans can’t match—ensuring your business stays efficient, competitive, and ready for the future of manufacturing.

(Need help choosing the right delta robot? Reach out to DeltaX for a consultation or watch more demos to see these robots in action!)